- HOME

- Product information

- Search by Functions and Features

- Mechanical properties

Product information - Search by Functions and Features

Search Result: Mechanical properties

The molecular structure and size is suitably controlled so as to make the "mechanical properties" of the products meet performance requirements of various applications, such as strength and flowing ability into molds for component manufacturing.

Fluon® ETFE

It has higher mechanical strength than other fluoropolymers.

Fluon®ETFE is a tough fluoropolymer that has chemical resistance and electrical properties comparable to typical fluoropolymers, such as PTFE, PFA and FEP but performs better than ECTFE or PVdF because of its improved mechanical strength and moldability.

- Pellet

- Powder

Fluon® LM-ETFE

It has higher mechanical strength than other fluoropolymers.

Fluon®LM-ETFE is a fluororesin which combines the excellent heat resistant and mechanical properties of ETFE resin and a low melting point

- Pellet

- Powder

Fluon® LM-ETFE AH Series

It has higher mechanical strength than other fluoropolymers.

AH Series

Fluon® LM-ETFE AH series products are fluoro resins with adhesive properties, making it possible to adhere to other materials by melting.

It can be applied directlywithout an adhesive agent or surface treatment as required by previous systems.

Excellent adhesiveness of a two-layer system is efficiently achieved in only one step.

- Pellet

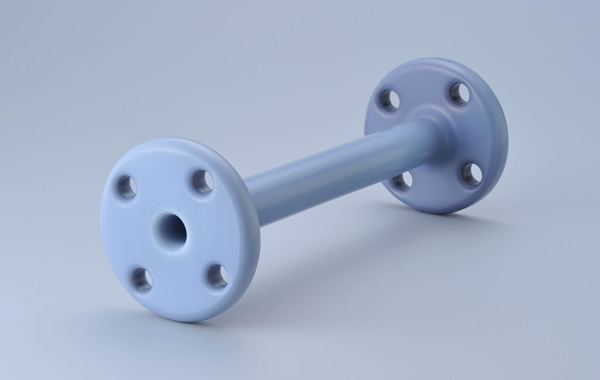

Fluon® PFA

Retains high mechanical strength and can be used within a wide operating temperature range from -200°C to +260°C.

Fluon® PFA is a copolymer of tetrafluoroethylene (C2F4) and perfluoroalkoxyethylene. PFA retains inherent characteristics and similar properties to PTFE but can be processed using thermoplastic techniques, such as injection molding, extrusion, and blow molding.

- Pellet

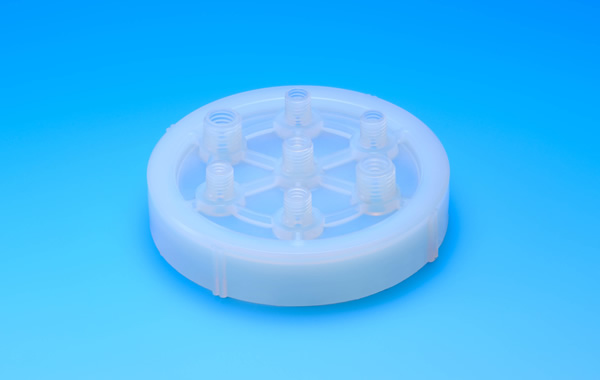

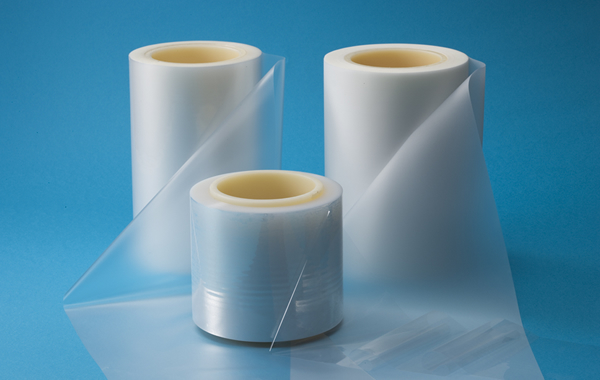

Fluon® ETFE Film

It is flexible, and demonstrates an uniaxial tensile elongation of 400% or more even under room temperature. Its strong non-adhesiveness and flexibility mean that it can be used as a release film for semiconductor package molding.

Fluon® ETFE Film is a high-performance fluoropolymer film manufactured by AGC from our raw material. Due to its excellent properties of heat resistance, chemical resistance, optical transparency, and non-adhesiveness, it has a wide variety of applications from electronics, aircrafts and solar cells to kitchen products and wallpaper.

- Film

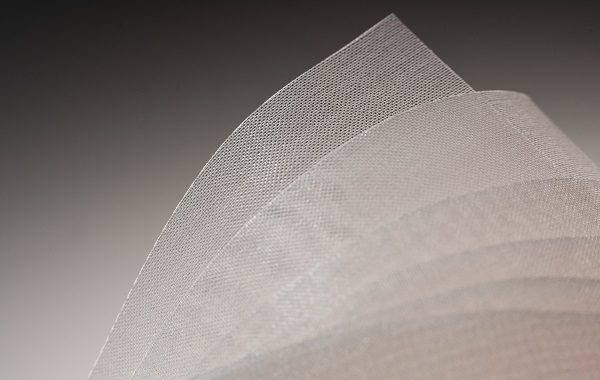

FORBLUE™ FLEMION™

A fluorinated cation exchange membrane developed by AGC for caustic soda/caustic potash/chlorine/hydrogen manufacturing that achieves substantial energy-savings. It is reinforced by PTFE cloth for extremely high mechanical strength.

“FLEMION™” is a fluorinated cation exchange membrane that offers extremely low resistance.With superior durability, it offers a long service life. It can reduce energy consumption and is used by customers all over the world.

FORBLUE™ S-SERIES

FORBLUE™ S-S-SERIES sustains high mechanical strength and is easy to handle by incorporating a special PTFE fiber reinforcement into sulfonic acid polymer film.

New addition to this family is FORBLUETM S-SERIES - fluorinated sulfonic acid ion exchange membranes for a wide variety of electrolysis and electro dialysis processes.