- HOME

- Product information

- Search by Functions and Features

- Heat resistance

Product information - Search by Functions and Features

Search Result: Heat resistance

Our fluoropolymer products have excellent "heat resistance" and "flame retardancy". Because of strong "carbon-fluorine bonds" of the molecules, they can be used under higher temperatures.

Fluon® ETFE

Performs well when used within a wide temperature range from -200 to +150°C, while maintaining stable mechanical and electrical properties. Continuous usage at +150°C is also possible.

Fluon®ETFE is a tough fluoropolymer that has chemical resistance and electrical properties comparable to typical fluoropolymers, such as PTFE, PFA and FEP but performs better than ECTFE or PVdF because of its improved mechanical strength and moldability.

- Pellet

- Powder

Fluon® LM-ETFE

It has higher heat resistance than ETFE resin and can be used within in a wide temperature range from -200 to +180°C, while maintaining stable mechanical and electrical properties. Continuous usage at +180°C is also possible.

Fluon®LM-ETFE is a fluororesin which combines the excellent heat resistant and mechanical properties of ETFE resin and a low melting point

- Pellet

- Powder

Fluon® LM-ETFE AH Series

It has higher heat resistance than ETFE resin and can be used within a wide temperature range from -200 to +180°C, while maintaining stable mechanical and electrical properties. Continuous usage at +180°C is also possible.

AH Series

Fluon® LM-ETFE AH series products are fluoro resins with adhesive properties, making it possible to adhere to other materials by melting.

It can be applied directlywithout an adhesive agent or surface treatment as required by previous systems.

Excellent adhesiveness of a two-layer system is efficiently achieved in only one step.

- Pellet

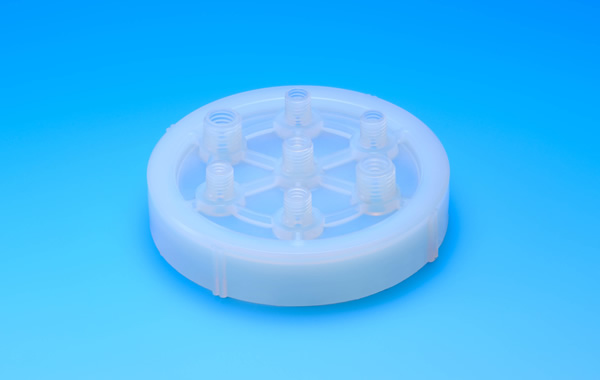

Fluon® PTFE

Performs well when used within in a wide temperature range from -180 to +260°C. Non-flammable material conforming to UL standards 94V-1.

PTFE accounts for 60-70% of the total demand for fluoropolymers. Although discovered over 60 years ago, applications are still being explored in new fields due to its numerous desired properties such as inertness, lubricity and heat resistance.

- Powder

- Dispersion

- Lubricant

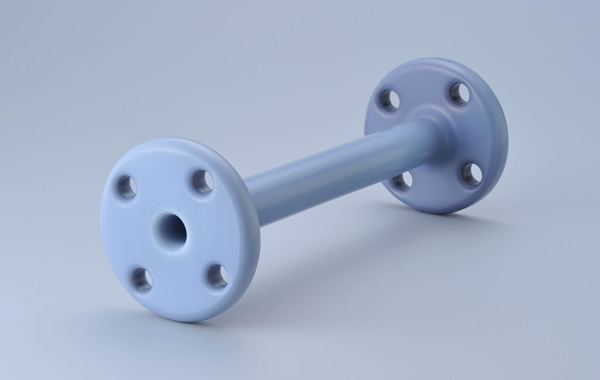

Fluon® PFA

Performs well when used a within wide temperature range from -180 to +260°C. Non-flammable material conforming to UL standards 94V-0.

Fluon® PFA is a copolymer of tetrafluoroethylene (C2F4) and perfluoroalkoxyethylene. PFA retains inherent characteristics and similar properties to PTFE but can be processed using thermoplastic techniques, such as injection molding, extrusion, and blow molding.

- Pellet

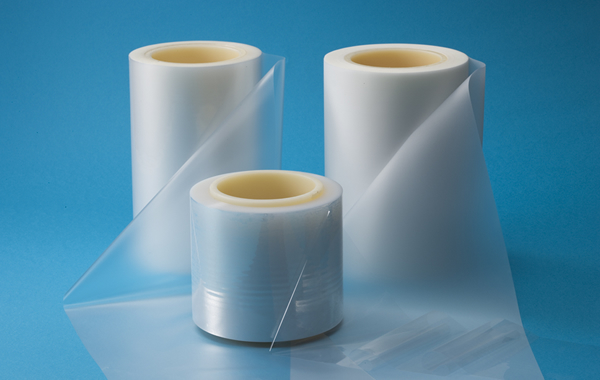

Fluon® ETFE Film

Fluon® ETFE Film is a UL standard 94VTM-0 flame retardant material that can be used in a wide range of temperatures (from -200°C to 200°C). It is well suited for a press process which requires high temperature.

Fluon® ETFE Film is a high-performance fluoropolymer film manufactured by AGC from our raw material. Due to its excellent properties of heat resistance, chemical resistance, optical transparency, and non-adhesiveness, it has a wide variety of applications from electronics, aircrafts and solar cells to kitchen products and wallpaper.

- Film