- HOME

- Product information

- Search by Category

- Thermoplastic fluoropolymers

Product information - Search by Category

Search Result: Thermoplastic fluoropolymers

They are fluoropolymers that are solid at room temperature, but can be melted by heating and then solidified by cooling, making them highly versatile in terms of processing methods.

Fluon® ETFE

Fluon® ETFE is a tough fluoropolymer that has chemical resistance and electrical properties comparable to typical fluoropolymers, such as PTFE, PFA and FEP but performs better than ECTFE or PVdF because of its improved mechanical strength and moldability.

Fluon®ETFE is a tough fluoropolymer that has chemical resistance and electrical properties comparable to typical fluoropolymers, such as PTFE, PFA and FEP but performs better than ECTFE or PVdF because of its improved mechanical strength and moldability.

- Pellet

- Powder

Fluon® LM-ETFE

It is a fluoropolymer with a low melting point and excellent physical properties possessed by fluoropolymers, such as high heat-resistance, mechanical properties and the like. Its melting point is low at 225°C, and it is able to maintain its low viscosity even up to around 240°C, making it possible to be molded at temperatures roughly 50°C lower than conventional ETFE.

Fluon®LM-ETFE is a fluororesin which combines the excellent heat resistant and mechanical properties of ETFE resin and a low melting point

- Pellet

- Powder

Fluon® LM-ETFE AH Series

Fluon® LM-ETFE AH series products are fluorinated resins with adhesive properties, making it possible to adhere to other materials by melting. It can be applied directly without adhesive agents or surface treatments as required in previous systems. Excellent adhesiveness of two-layer systems is efficiently in only one step. Desired properties such as anti stick, ETFE moldability and chemical resistance are the same as those of conventional ETFE.

AH Series

Fluon® LM-ETFE AH series products are fluoro resins with adhesive properties, making it possible to adhere to other materials by melting.

It can be applied directlywithout an adhesive agent or surface treatment as required by previous systems.

Excellent adhesiveness of a two-layer system is efficiently achieved in only one step.

- Pellet

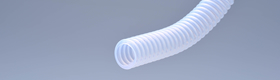

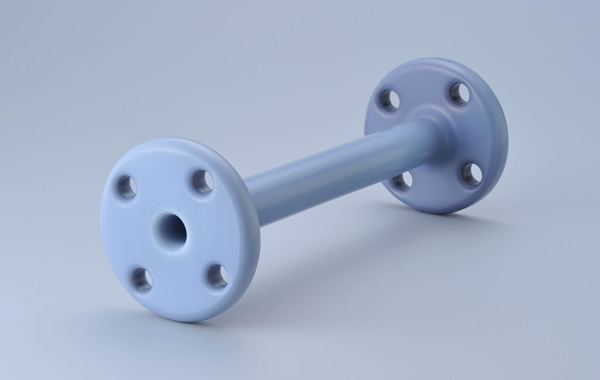

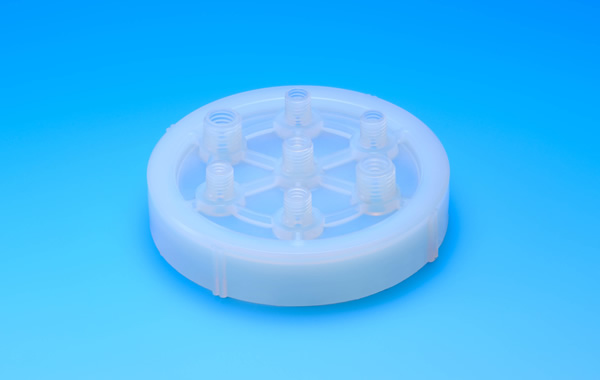

Fluon® PFA

Fluon® PFA is a copolymer of tetrafluoroethylene (C2F4) and perfluoroalkoxyethylene. PFA retains inherent characteristics and similar properties to PTFE but can be processed using thermoplastic techniques, such as injection molding, extrusion, and blow molding.

Fluon® PFA is a copolymer of tetrafluoroethylene (C2F4) and perfluoroalkoxyethylene. PFA retains inherent characteristics and similar properties to PTFE but can be processed using thermoplastic techniques, such as injection molding, extrusion, and blow molding.

- Pellet

CYTOP®

Due to a thermoplastic resin with a glass transition temperature of 108°C, it is possible to apply the molding processing by using heat.

Because CYTOP® has an amorphous structure, it can achieve extremely high transparency, and since it dissolves in an exclusive fluorine-based solvent, thin film coating is possible. Furthermore, it is a fluoropolymer with the characteristics including “transparency”, “low refractivity”, “electrical insulation”, “water and oil repellency”, and “chemical resistance”.

- Solution