Product information - Search by Field and Use

Search Results [Medical-related and living essentials] > [Medical devices]

The "chemical resistance" and "electrical properties" of fluoropolymers are used in various medical equipment parts.

LUMIFLON®

Taking advantage of the chemical resistance of fluoropolymers, it is used as an ingredient in coatings for medical device parts.

LUMIFLON® is the world first solvent-soluble fluoropolymer developed by AGC in 1982. LUMIFLON® is used as an ingredient for various types of paints and coatings (including corrosion protection and architectural application), the weatherability of fluoropolymer protects substrates and maintains an attractive appearance for a long time.

- Liquid (solvent-based/water-based)

- Solid (powder)

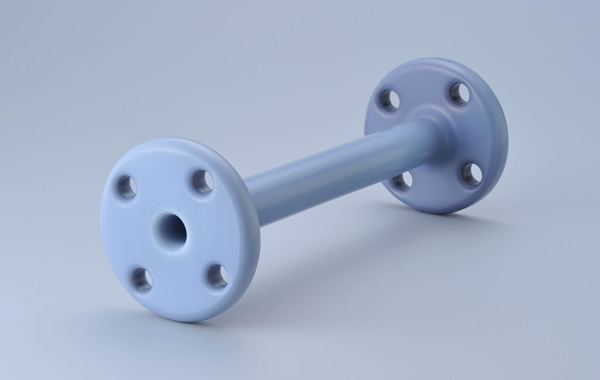

Fluon® ETFE

The chemical resistance and electrical properties of Fluon® ETFE are beneficial for use in various medical equipment parts.

Fluon®ETFE is a tough fluoropolymer that has chemical resistance and electrical properties comparable to typical fluoropolymers, such as PTFE, PFA and FEP but performs better than ECTFE or PVdF because of its improved mechanical strength and moldability.

- Pellet

- Powder

Fluon® PTFE

The chemical resistance and electrical properties of Fluon® PTFE are beneficial for use in various medical equipment parts.

PTFE accounts for 60-70% of the total demand for fluoropolymers. Although discovered over 60 years ago, applications are still being explored in new fields due to its numerous desired properties such as inertness, lubricity and heat resistance.

- Powder

- Dispersion

- Lubricant

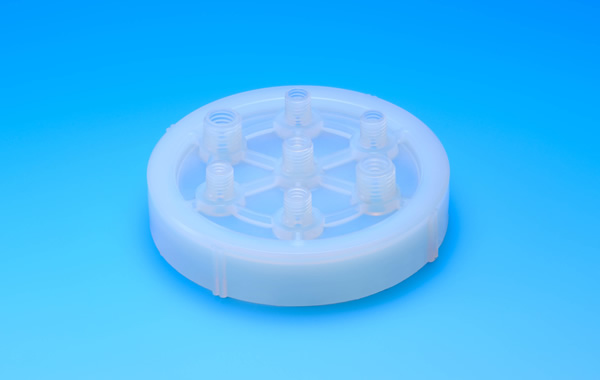

Fluon® PFA

The chemical resistance and electrical properties of Fluon® PFA are beneficial for use in various medical equipment parts.

Fluon® PFA is a copolymer of tetrafluoroethylene (C2F4) and perfluoroalkoxyethylene. PFA retains inherent characteristics and similar properties to PTFE but can be processed using thermoplastic techniques, such as injection molding, extrusion, and blow molding.

- Pellet

CYTOP®

Due to its properties of “oil and water repellency”, “chemical resistance”, “transparency” and the like, it is used and suitable for “medical devices” applications.

Because CYTOP® has an amorphous structure, it can achieve extremely high transparency, and since it dissolves in an exclusive fluorine-based solvent, thin film coating is possible. Furthermore, it is a fluoropolymer with the characteristics including “transparency”, “low refractivity”, “electrical insulation”, “water and oil repellency”, and “chemical resistance”.

- Solution