- HOME

- Product information

- Fluon®

- Fluon® PTFE

- Fluon® PTFE FC

Fluon® PTFE FC

Fluon® PTFE FC has improved creep and wear resistance. A wide range of fillers such as glass fiber, graphite, bronze, carbon fiber and more are available.

Fluon® PTFE FC Usage

Fluon® PTFE FC Usage

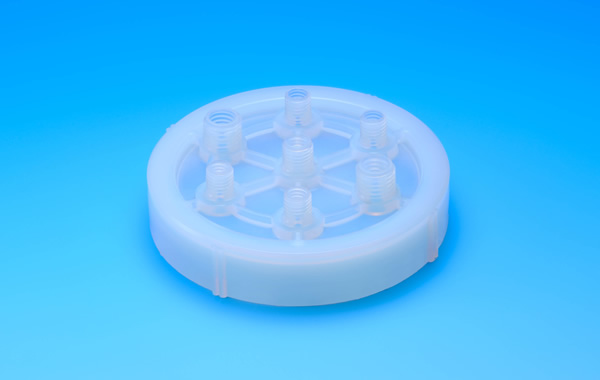

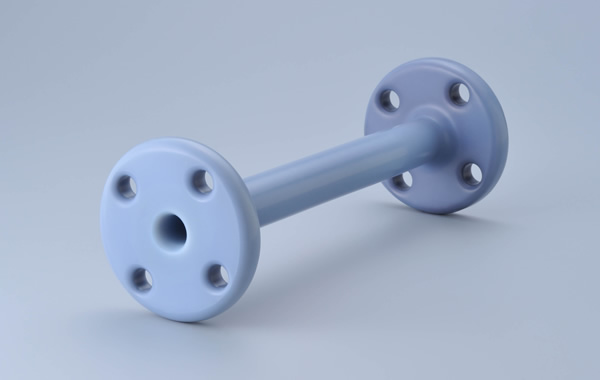

The following are examples of uses for the FC grade (containing filling materials).

Gaskets, packing, V-rings

Piston rings

Bearing bushes

Grade List

| Properties | Filler Type and Content (%) | Bulk Density | Median Particle Size | Tensile Strength | Elongation | Specific Gravity | Applications | Characteristics |

|---|---|---|---|---|---|---|---|---|

| Units | g/l | μm | Mpa | % | - | |||

| PA1015SZ | Glass fiber (15%) | 880 | 730 | 26.2 | 360 | 2.22 | Bearings Gaskets Discs for valves V-rings, O-rings Plug valve seats Pump impellers Mechanical seals | Improved wear resistance, Improved compression resistance, Filler can be damaged by strong amines and hydorgen fluoride, Improved powder flow for Z-type of PA. |

| RB1015S | 510 | - | 27.9 | 310 | 2.21 | |||

| PA1020Z | Glass fiber (20%) | 890 | 660 | 21.7 | 350 | 2.24 | ||

| PA1025Z | Glass fiber (25%) | 860 | 730 | 18.5 | 340 | 2.23 | ||

| RB1025S | 480 | - | 25.0 | 320 | 2.22 | |||

| PB2015 | Graphite (15%) | 670 | 730 | 15.2 | 200 | 2.14 | Piston rings Bearings Gaskets Shock absorbers | Enhanced creep resistance, Chemical resistance, Low coefficient of friction, Improved load resistance |

| RB2015 | 410 | - | 21.9 | 275 | 2.14 | |||

| PB2215H | Graphite (14%) + Carbon fiber (1%) | 680 | 560 | 17.2 | 240 | 2.13 | ||

| PB3060 | Bronze (60%) | 1340 | 760 | 20.0 | 290 | 3.85 | Bearings | Improved wear and creep resistance, High conductivity because of metal filler, Anti-oxidizing for PB3360 |

| PB3360T | 1330 | 700 | 18.0 | 300 | 3.94 | |||

| PB2510 | Carbon fiber (10%) | 670 | 620 | 25.0 | 300 | 2.07 | Shaft bearings Bearings Piston rings Ball valve seats Bearing pads Oil seals | Improved wear resistance in water, Improved load resistance, Improved bending strength |

| RB2510 | 440 | - | 30.0 | 330 | 2.08 | |||

| PB2515 | Carbon fiber (15%) | 650 | 620 | 20.5 | 270 | 2.02 | ||

| PB1205 | Glass fiber (20%) + Graphite (5%) | 760 | 700 | 16.0 | 250 | 2.21 | Bearings Piston rings Mechanical seals Ball valve seats | Improved wear resistance, Improved creep resistance, Improved stiffness and hardness |

| PB1211 | Glass fiber (15%) + Molybdenum disulfide (5%) | 790 | 700 | 21.5 | 305 | 2.27 | ||

| RB1211 | 470 | - | 25.2 | 320 | 2.28 | |||

| PB1202 | Glass fiber (16%) + Graphite (2%) + Proprietary filler (2%) | 750 | 650 | 19.0 | 300 | 2.24 | ||

| PA3540LT | Bronze (30%) + Carbon fiber (10%) | 940 | 710 | 13.5 | 285 | 2.66 | Bearings Packing | Improved load resistance, Improved wear resistance, Improved stiffness and hardness |

| RA3540G | 620 | - | 17.1 | 365 | 2.64 | |||

| RA7003 | Proprietary filler (3%) | 420 | - | 33.8 | 360 | 2.15 | Antistatic components | Semi-conductive |

| PA7115 | Polyimide (15%) | 700 | 650 | 17.6 | 360 | 1.95 | Packing Oil seals | Improved tear resistance, Reduced scratch occurrence |

Measurement properties are based on JIS K-6891.

PA, PB : Good powder flow

RA, RB : Regular powder

S : Dark center free

Z : High bulk density, High powder flow

T : Discoloration resistance

Information about this Product

Inquiries about this Product

We also accept requests for samples, and consultations regarding introduction and verification support.