- HOME

- Product information

- Fluon®

- Fluon® ETFE

- Fluon® ETFE

Fluon® ETFE

Fluon®ETFE is a tough fluoropolymer that has chemical resistance and electrical properties comparable to typical fluoropolymers, such as PTFE, PFA and FEP but performs better than ECTFE or PVdF because of its improved mechanical strength and moldability.

Fluon® ETFE Functions and Features

Versatile moldability

Extrusion, injection molding and powder coating using ETFE are generally possible, similar to general thermoplastic resins, leaving the inherent characteristics of fluoropolymers unchanged. Filming, heat-sealing, composition with rubber and various secondary processes are also possible.

Heat resistance

Stable mechanical electrical properties are maintained over a wide range of temperatures, -200 - +180°C. Continuous service at 150°C is possible.

Chemical resistance

It exhibits outstanding chemical resistance to nearly all chemical substances, including strongly-acidic and strongly-alkaline substances.

Fluon® ETFE Usage

The characteristics of Fluon®ETFE provide the superior solution, in terms of cost reduction compared to the use of other fluoropolymers, or improved performance if replacing conventional materials.

Fluon® ETFE Usage

The following is an introduction of the major uses of Fluon® ETFE.

Wire and cable

Due to its excellent electrical and insulating properties in a wide range of temperatures, and superior mechanical strength, especially flex life, Fluon®ETFE is suitable for wire and cable coatings.

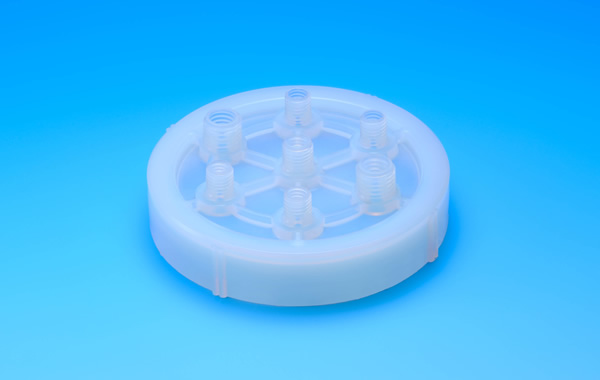

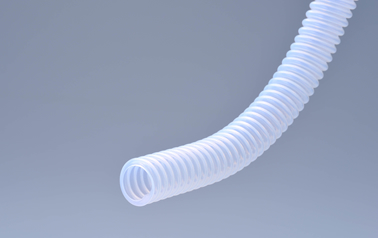

Tubing

Tubing made from Fluon® ETFE is suitable for the transportation of high viscosity liquid, due to its non-adhesiveness and smoothness of internal molded surfaces.

Linings and coatings

Fluon®ETFE, when used as an inner layer lining or coating, is stable against most chemicals (acids, alkali, solvent, etc.) and remains effective when subjected to an increase or decrease in temperature or pressure.

Grade List

■ Pellet

| Grade | Melt Flow Rate* | Features | Molding Methods and Applications |

|---|---|---|---|

| C-55AP | 5 - 7 | General product | Extrusion molding |

| C-88AP | 10 - 13 | General product | Extrusion molding |

| C-55AXP | 5 - 7 | Resistant to stress cracking | Extrusion molding, tube molding |

| C-88AXP | 10 - 13 | Resistant to stress cracking | Injection molding, electric wire coatings |

| C-88AXMP | 30 - 48 | High fluidity | Thin electric wires, thin-walled injection |

| CF-5020X | 5 - 10 | Low contractibility, carbon fiber 20% | Injection molding, chemical pump parts |

| CB-8015X | 1 - 3.5 | Conductivity, carbon 15% | Extrusion molding, fuel tubes |

■ Powder

| Grade | Thickness | Molding Method | Characteristics |

|---|---|---|---|

| Z-8820X | 50 - 80 μm | Electrostatic powder coating | Non-adhesive; confectionery production equipment, etc. |

| Z-882NX | 50 - 80 μm | Electrostatic powder coating | Non-adhesive; confectionery production equipment, etc. |

| Z-885C | 50 - 150 μm | Electrostatic powder coating | Non-adhesive; rolls, etc. |

| 50 - 400 μm | Fluidized bed coating | Corrosion resistant; plant equipment, etc. | |

| TL-081 | ~ 1000 μm | Electrostatic powder coating | Highly corrosion resistant; reaction tanks, storage tanks, piping, pumps, tanker trucks, etc. |

| ~ 1000 μm | Fluidized bed coating | ||

| ZL-522F | more than 2000 μm | Rotational molding | Highly corrosion resistant; reaction tanks, storage tanks, piping, pumps, tanker trucks, etc. |

| TL-580 | more than 2001 μm | Rotational molding | Cracking resistance, high fluidity |

| TL-581 | more than 2002 μm | Rotational molding | Highly corrosion resistant; reaction tanks, storage tanks, piping, pumps, tanker trucks, etc. |

| TL-584 | more than 2003 μm | Rotational molding | Cracking resistance, high fluidity, high heat-resistance |

| ZL-520N | ~ 1000 μm | Electrostatic powder coating | Corrosion resistant, low contractibility, contains CF 20 wt% |

| ~ 1000 μm | Fluidized bed coating | ||

| ZL-521N | 50 - 150 μm | Electrostatic powder coating | For overcoating of ZL-520N, low contractibility, contains CF 5 wt% |

| 50 - 400 μm | Fluidized bed coating | ||

| CP-801XGN | 50 - 100 μm | Electrostatic powder coating | For undercoating |

Information about this Product

Inquiries about this Product

We also accept requests for samples, and consultations regarding introduction and verification support.