- HOME

- Product information

- Fluon®

- Fluon® PFA

- Fluon® PFA Functions and Features

Fluon® PFA - Functions and Features

Fluon® PFA Functions and Features

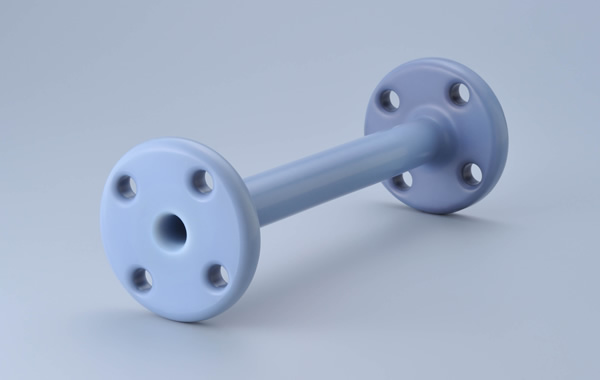

Versatile Processability

PFA enables more flexible processing using thermoplastic techniques, such as injection molding, extrusion, and blow molding.

Electrical Properties

PFA is an outstanding electrical insulating material having extremely low dielectric constant and dielectric tangent. Using PFA for electrical components ensures their reliability.

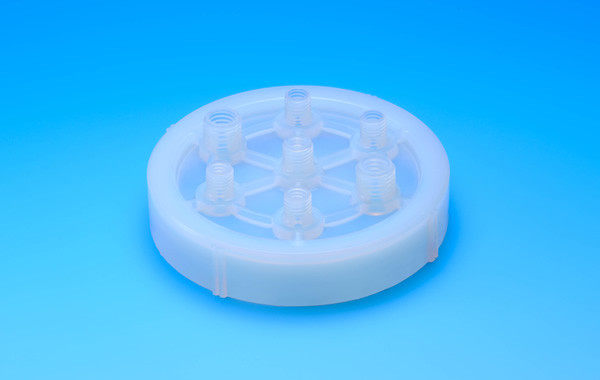

Chemical Resistance

PFA has high chemical stability and is not affected by most chemicals. PFA is ideal for molding materials of semiconductors that are constantly exposed to highly active chemicals.

Mechanical Strength Retention

PFA retains high mechanical strength and can be used stably in a wide temperature range from -200 to +260°C.

Flame Resistance

With an oxygen index of 95% or higher, its properties as a non-combustible material can broaden its application in a wide variety of fields.

Low Surface Energy

PFA has good surface properties, e.g. low coefficient of friction, anti-adhesion and water/oil repellency that allow for excellent flow of substances.

Weather Resistance

PFA is virtually not deteriorated by direct sunlight, wind, rain, or exhaust gas. The characteristics of PFA hardly change even with prolonged outdoor exposure.

Fluon® Product Lineup

Information about this Product

Inquiries about this Product

We also accept requests for samples, and consultations regarding introduction and verification support.