- HOME

- AGC Chemicals Information

- AGC Chemicals Vision

- Innovation Story

- Innovation Story 02 Aiming to Realize a “Circular Fluorine Society”

Innovation Story

Aiming to Realize

a “Circular Fluorine Society”

Waste fluorine is collected as “Recycled Circular Fluorite”

Fluorine serves as a high-performance element that supports our daily lives and industries, and a key component in materials that are used across various fields such as semiconductors, automotive, construction, and aerospace. However, its raw material, natural fluorite, is a scarce resource, making stable procurement a challenge. At AGC, we are striving to realize a “circular fluorine society,” which aims to balance environmental conservation with the convenience that humanity has built, through the use of “recycled circular fluorite” and technologies for recycling of used fluorine.

- Fluorine is an essential chemical element for daily life and industrial society.

- “Natural Fluorite,” which is the raw material for fluorine, is a rare resource produced only in specific countries.

- “Global Environmental Conservation” and “Maintaining High Functionality”: Toward the realization of a sustainable “Circular Fluorine Society” from two perspectives.

- Waste fluorine is collected as “Recycled Circular Fluorite.” Topics

AGC has obtained the “UL2809 Validation” for the fluoropolymer resin “Fluon® PTFE” using mass balance method. - Taking on the challenge of realizing a “Circular Fluorine Society” as a practice of “Chemistry for a Blue Planet.”

- Contributing to the Achievement of the SDGs

-

What are the SDGs?

What are the SDGs?

Fluorine is an essential chemical element for daily life and industrial society.

Fluorine is an essential chemical element for daily life and industrial society.

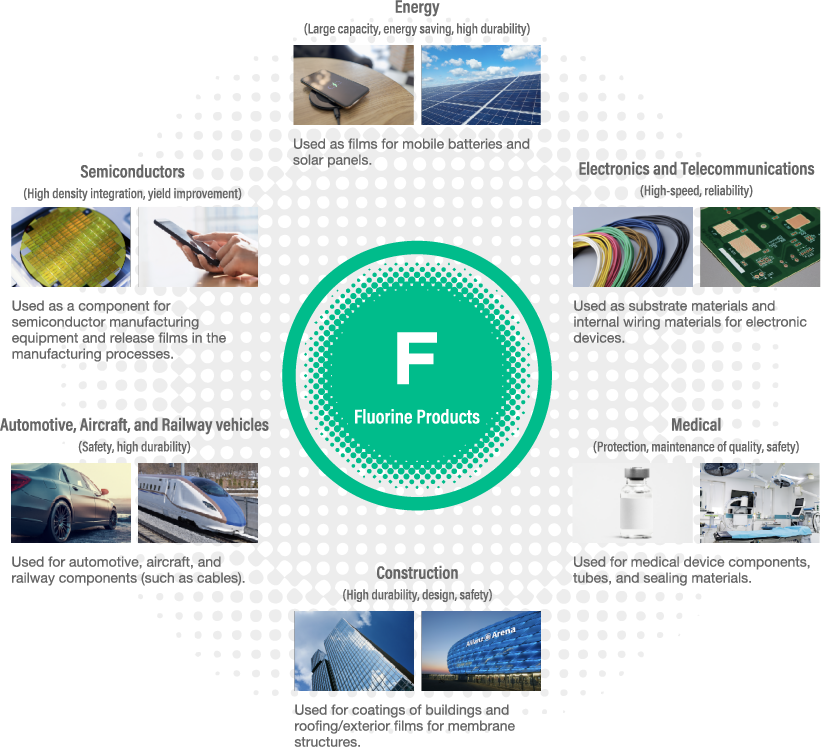

The fluorochemical products business of AGC Chemicals Company utilizes its unique fluorochemical core technology to develop a diverse range of applications that support modern industry. The outstanding properties of fluorine compounds, such as heat resistance, chemical resistance, and electrical insulation, make them indispensable in a wide range of industrial fields.

The product lineup ranges from fluorinated gases to various fluoropolymers. As process components in semiconductor manufacturing processes, they support the production of cutting-edge devices. Moreover, our products are also used in fuel hoses and sealing materials in the automotive field, meeting stringent performance requirements. Furthermore, they play an important role in applications requiring safety and reliability, such as coatings for high-voltage cables in trains, lightweight and durable parts for aerospace equipment, and roof/exterior materials for membrane building structures where flexible design is required in the construction field. AGC's fluorochemical products will continue to evolve as essential materials that support industrial infrastructure aimed at realizing a sustainable society.

“Natural Fluorite,” which is the raw material for fluorine, is a rare resource that is only produced in specific countries.

“Natural Fluorite,” which is the raw material for fluorine, is a rare resource that is only produced in specific countries.

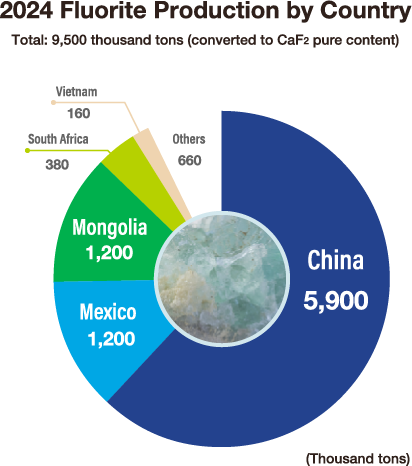

Fluorite, a raw material for fluorine-based products, is a natural mineral resource whose main component is calcium fluoride (CaF₂). China accounts for approximately 62% of global fluorite production, followed by Mexico and Mongolia at 12.6% each. Together, in 2024, these three countries accounted for 87% of global production*. This extremely uneven distribution of production areas makes natural fluorite a highly scarce strategic resource. As a result, it has been designated a critical material in Japan, the United States, and Europe, making stable procurement an issue.

In response to these supply risks, AGC is developing a long-term procurement strategy. By securing multiple procurement routes, we continue to fulfill our social responsibility of providing a stable supply of fluorochemical products that support advanced industries.

However, based on the recoverable reserves (320,000,000 metric tons*) and production volume, it is possible that the world’s mineable natural fluorite may be depleted in approximately 30 years.

- * Mineral Commodity Summaries 2025, USGS

“Global Environmental Conservation” and “Maintaining High Functionality”: Toward the realization of a sustainable “Circular Fluorine Society” from two perspectives.

“Global Environmental Conservation” and “Maintaining High Functionality”: Toward the realization of a sustainable “Circular Fluorine Society” from two perspectives.

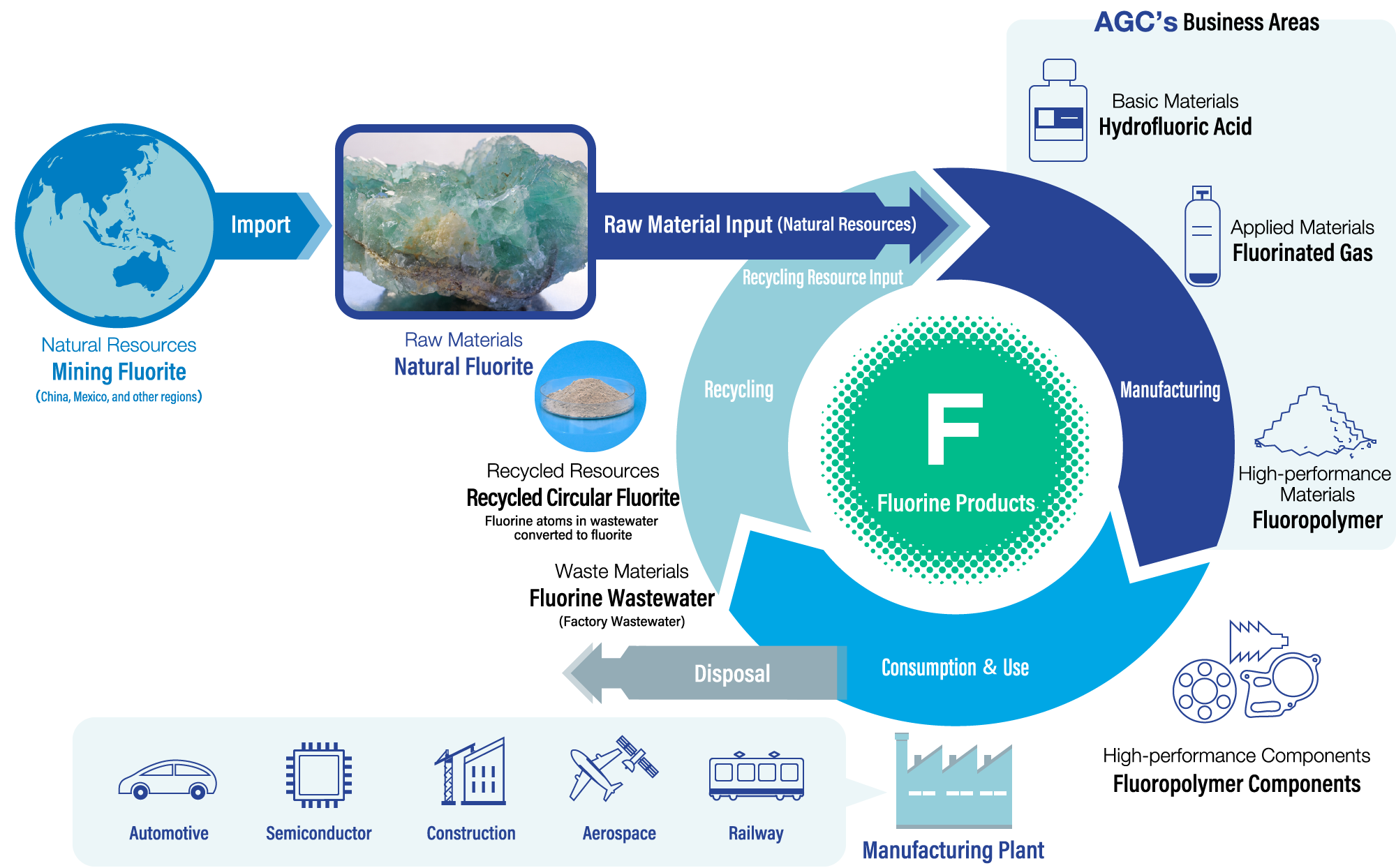

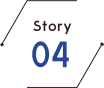

Fluorine plays a major role in improving convenience through the high functionality of products used in many industries. How can we maintain the benefits that humanity has built while protecting the global environment and achieving a balance between the two? To achieve this, we need technology that can regenerate fluorine and return it to the raw material so that it can be used for fluorochemical products. However, most fluorochemical products are currently discarded after use, and fluorine ions in wastewater are collected as sludge. As a result, that fluorine cannot be used effectively.

Given this situation, it is expected that the fluorine extracted from natural fluorite will be recycled in various ways, enabling it to be used continuously. We aim for a “circular fluorine society” where this important fluorine is circulated throughout the global supply chain, thereby supporting people's lives.

Circular Fluorine Society

Waste fluorine is collected as “Recycled Circular Fluorite.”

Waste fluorine is collected as “Recycled Circular Fluorite.”

One of the methods in this cycle is based on the concept of “recycled circular fluorite.” AGC has been attempting to recover fluorine from wastewater as fluorite and recycling it. Conventionally, the fluorite collected from wastewater had various issues, such as not being pure enough to be used as a raw material for fluorine-based chemical products. As a result, it was either used for applications where fluorine was essentially not required or discarded. However, leveraging its diverse expertise and improving the purity and other properties of the fluorite recovered from wastewater, AGC has succeeded in producing “recycled circular fluorite” at a level that allows it to be reused in fluorochemical products. This makes it possible to recycle fluorine derived from natural fluorite.

AGC uses this technology to manufacture recycled fluorite in-house, and is working on recycling by collecting materials from outside the company.

Topics

AGC has obtained the “UL2809 Validation” for the fluoropolymer resin “Fluon® PTFE” using mass balance method.

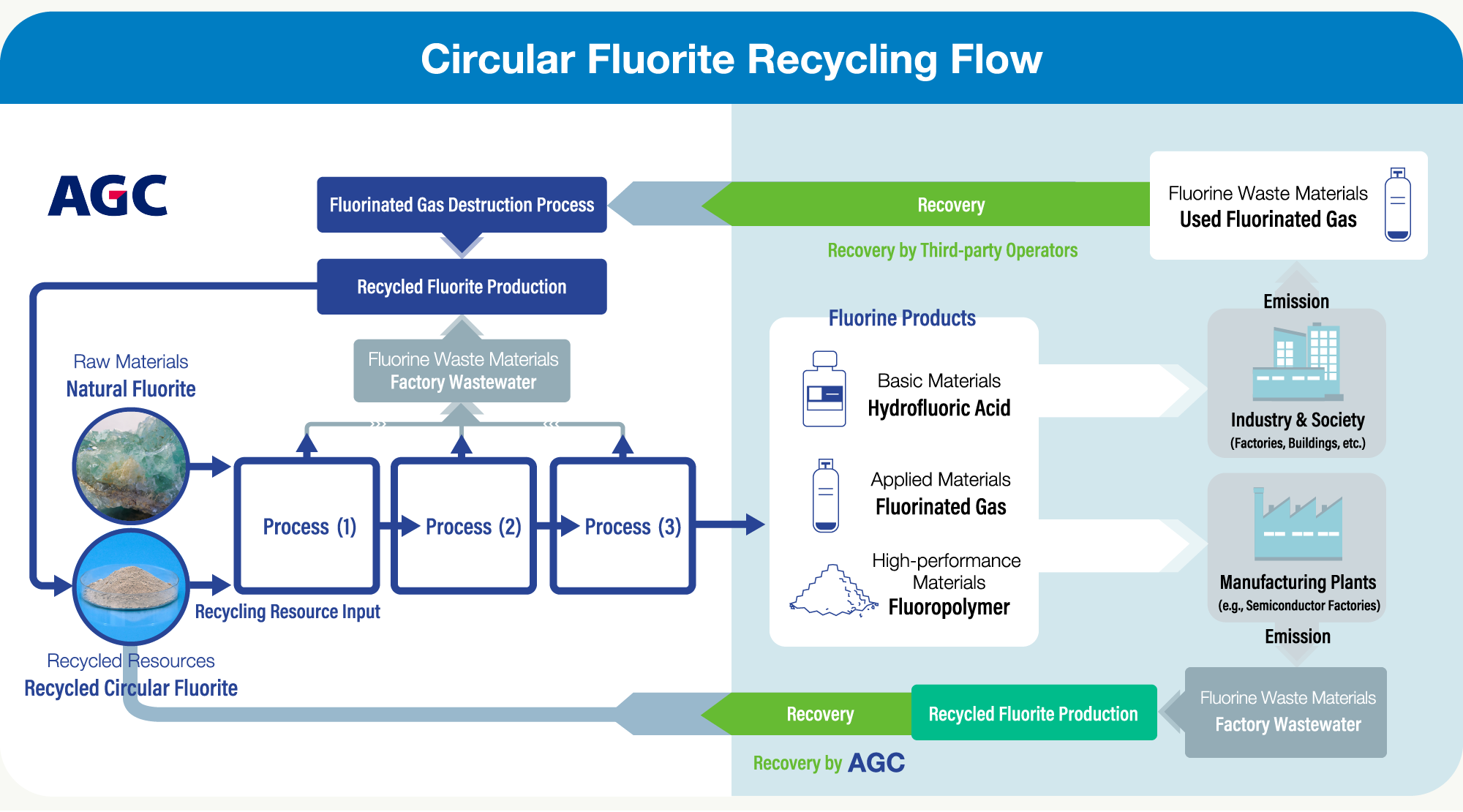

AGC has now obtained “UL2809 Validation” for Fluon® PTFE G grade (molding powder grade). UL2809 Validation is a system in which a third-party organization validates declarations based on the self-declared environmental claims under ISO14021. This validation means that the reliability of the percentage of “recycled circular fluorite” in products, as declared by AGC using the mass balance method,” is guaranteed by a third-party organization.

AGC aims to realize a “circular fluorine society” by creating a system for the recycling of fluorine atoms.

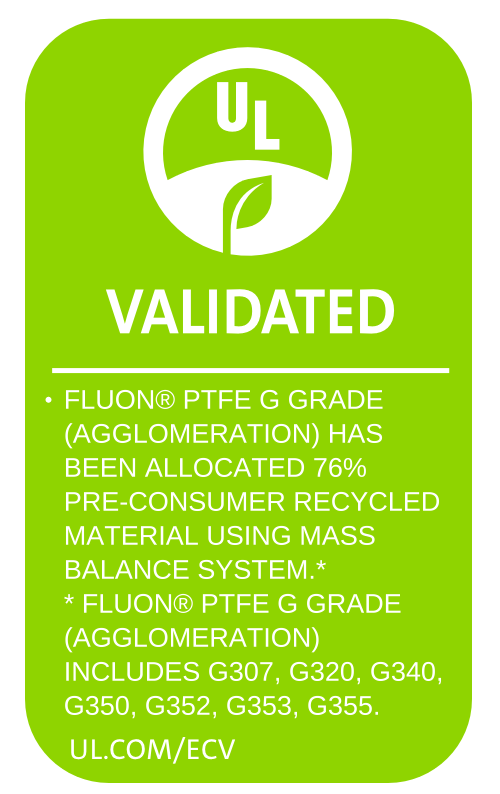

* The mass balance method is a method of assigning characteristics to manufactured products according to the ratio of raw materials with the specific characteristics to the input of raw materials in the manufacturing process. For example, if 20% of the fluorite used in the overall manufacturing process is “recycled circular fluorite,” 20% of all products produced in that manufacturing process will be considered to have been made using 100% “recycled circular fluorite.” On the other hand, the remaining 80% of the products will be considered as made using 0% “recycled circular fluorite.”

Taking on the challenge of realizing a “Circular Fluorine Society” as a practice of “Chemistry for a Blue Planet.”

Taking on the challenge of realizing a “Circular Fluorine Society” as a practice of “Chemistry for a Blue Planet.”

AGC aims to create a “circular fluorine society” by increasing the amount of “recycled circular fluorite” used and raising the fluorine recycling rate, thereby preventing the depletion of fluorine worldwide and creating a safe, secure, comfortable and environmentally friendly world for people. Furthermore, we believe that building a circular fluorine economy by combining not only “recycled circular fluorite” but also a variety of other recycling methods is our wish, goal, and responsibility as a leading supplier of fluorochemical products.