- HOME

- Products and Service Information

- EXCESTAR <General Name > Silane Modified Polyether

EXCESTAR <General Name > Silane Modified Polyether

Product summary

This is a moisture hardened modified silicone polymer with a hydrolyzed silyl group on the end, and developed based on ultra high molecular weight polyether polyol (Preminol) technology.

It hardens due to moisture in the presence of a catalyst to become a flexible elastic medium. It is used as a base polymer for sealing materials, adhesives, etc.

Features

Excestar is a groundbreaking moisture hardened liquid polyether polymer with a hydrolyzed silyl group on the end, and developed based on AGC Chemicals' ultra high molecular weight polyether polyol (Preminol) technology.

It hardens due to moisture in the air in the presence of a catalyst to become an elastic medium.

Excestar has physical properties suited for sealants and adhesives by mixing with various types of fillers.

You will be able to obtain an elastic medium.

General name: sealant polymer adhesive polymer

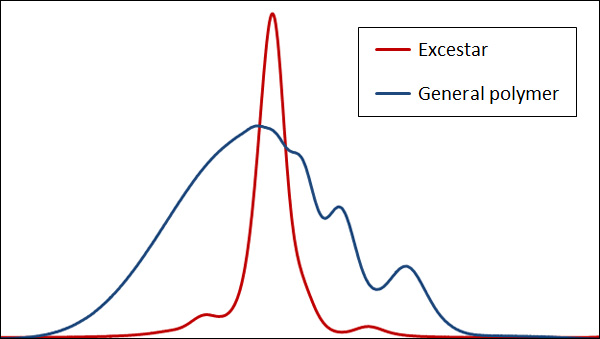

Molecular weight distribution is sharp.

・ Excels in hardness

・ High strength, high elongation

・ Low viscosity

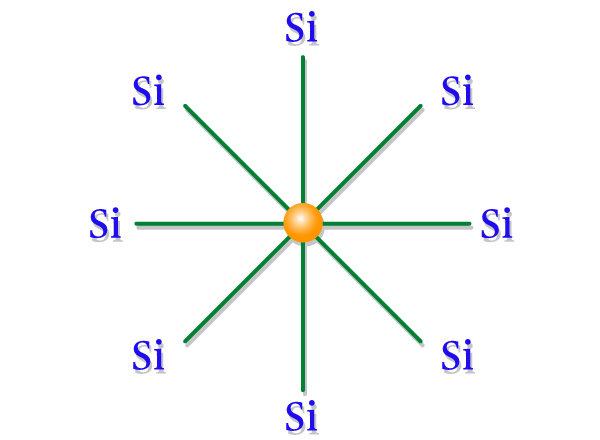

Easily polyfunctionalized

・ Modulus can be easily increased

・ Viscosity can be reduced

Main uses

Sealing material for construction, elastic adhesive, coating material, other general sealing materials, etc.

Basic characteristics

Representative product numbers are shown below.

| Properties | Appearance | Viscosity (mPa・s at 25°C) | Characteristics |

|---|---|---|---|

| ES-S2410 | Light yellow liquid | 11,000~20,000 | Low modulus, high elongation |

| ES-S2420 | Light yellow liquid | 12,000~23,000 | Middle modulus |

| ES-S3430 | Light yellow liquid | 6,000~13,000 | High modulus, low viscosity |

| ES-S3630 | Light yellow liquid | 14,000~23,000 | High modulus, middle elongation |

Hardening properties

Because the ES-S series has a hydrolyzed silyl group on the end,

hardened material with excellent flexibility and elasticity can be obtained by moisture.

Standard hardening properties are shown below.

| Properties | 50%-Tensile Stress (N/mm2) | Maximum Tensile Stress (N/mm2) | Rupture Elongation (%) |

|---|---|---|---|

| ES-S2410 | 0.08~0.15 | 0.30~0.80 | 300~500 |

| ES-S2420 | 0.15~0.25 | 0.40~0.90 | 200~400 |

| ES-S3430 | 0.25~0.35 | 0.30~0.80 | 100~300 |

| ES-S3630 | 0.25~0.35 | 0.40~0.90 | 200~400 |

Durability of hardened material

The ES-S series displays excellent heat resistance, hot water resistance and weather resistance.

Durability is shown below.

| Item's Stock Number | ES-S2410 | ES-S2420 |

|---|---|---|

| Initial Physical Properties1) 50%-Tensile Stress (N/mm2) Maximum Tensile Stress (N/mm2) Rupture Elongatio (%) | 0.11 0.5 390 | 0.20 0.62 320 |

| After Heating2) 50%-Tensile Stress (N/mm2) Maximum Tensile Stress (N/mm2) Rupture Elongation (%) | 0.12 0.51 440 | 0.19 0.61 310 |

| After immersing in hot water3) 50%-Tensile Stress (N/mm2) Maximum Tensile Stress (N/mm2) Rupture Elongatio (%) | 0.09 0.5 470 | 0.15 0.54 350 |

- 12 mm thick polymer sheet properties (DBTDL catalyst)

- 2Heating conditions: after heating at 100°C x 7 days

- 3Hot water immersion conditions: after immersing at 50°C x 7 days

Packing

Packing is in drums (200 kg).

Please select to match your intended use.

Warnings for use

Please wear protective glasses and protective gloves when handling.

*Please refer to the SDS for more detailed product information.

Production plant

■ AGC Inc. (Japan) Kashima Plant

Catalog download

For catalog download (English and Chinese), please click the following link and contact us.